| ||||||||||||||||||||||||

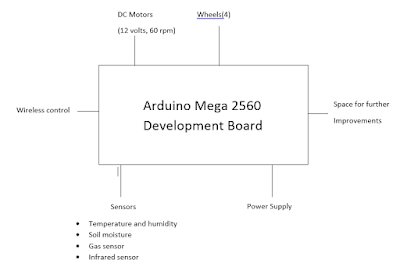

| Block Diagram

ARDUINO

Arduino

is an open-source computer hardware and software company, project and

user community that designs and manufactures kits for building digital devices

and interactive objects that can sense and control the physical world.

Arduino started in 2005 as a project for students at the Interaction

Design Institute Ivrea

in Ivrea, Italy. At that time program students used a "BASIC Stamp" at a cost of $100, considered expensive for

students. Massimo Banzi, one of the founders, taught at Ivrea. The name

"Arduino" comes from a bar in Ivrea, where some of the founders of

the project used to meet.

This project uses Arduino MEGA 2560 development board.

The Arduino Mega

2560 is a microcontroller board based on the ATmega2560. It has 54 digital

input/output pins (of which 15 can be used as PWM outputs), 16 analog inputs, 4

UARTs (hardware serial ports), a 16 MHz crystal oscillator, a USB connection, a

power jack, an ICSP header, and a reset button. It contains everything needed

to support the microcontroller; simply connect it to a computer with a USB

cable or power it with a AC-to-DC adapter or battery to get started.

SPECIFICATIONS AND PIN CONFIGURATION

The board can operate on an external

supply of 6 to 20 volts. If supplied with less than 7V, however, the 5V pin may

supply less than five volts and the board may be unstable. If using more than

12V, the voltage regulator may overheat and damage the board. The recommended

range is 7 to 12 volts.

The power pins are as follows:

Each of the 54 digital pins on

the Mega can be used as an input or output, using pinMode(), digitalWrite(), and digitalRead() functions. They operate at 5 volts. Each pin can

provide or receive a maximum of 40 mA and has an internal pull-up resistor

(disconnected by default) of 20-50 kOhms. In addition, some pins have

specialized functions:

The Mega2560 has 16 analog

inputs, each of which provide 10 bits of resolution (i.e. 1024 different

values). By default they measure from ground to 5 volts, though is it possible

to change the upper end of their range using the AREF pin and analogReference()

function.

There are a couple of other pins

on the board:

Programming

The Arduino Mega can be

programmed with the Arduino software.

The ATmega2560

on the Arduino Mega comes preburned with a bootloader that allows you

to upload new code to it without the use of an external hardware programmer. It

communicates using the original STK500 protocol.

The Arduino integrated development environment

(IDE) is a cross-platform application written in Java, and derives from the IDE for the Processing programming language

and the Wiring projects. It is designed to

introduce programming to artists and other newcomers unfamiliar with software

development. It includes a code editor with features such as syntax highlighting, brace

matching, and automatic indentation, and is also capable of compiling and

uploading programs to the board with a single click. A program or code written

for Arduino is called a sketch.

Arduino programs are written in C or C++. The Arduino

IDE comes with a software library called "Wiring" from the original Wiring

project, which makes many common input/output operations much easier. Users

only need define two functions to make a runnable cyclic

executive program:

SENSORS :

SOIL

MOISTURE SENSOR :

Soil

moisture sensors measure the water content in soil.

A soil moisture probe is made up of multiple soil moisture sensors. Since

analytical measurement of free soil moisture requires removing a sample and

drying it to extract moisture, soil moisture sensors measure some other

property, such as electrical resistance, dielectric constant, or interaction

with neutrons, as a proxy for moisture content. The relation between the

measured property and soil moisture must be calibrated and may vary depending

on soil type.

Specifications

TEMPERATURE

AND HUMIDITY SENSOR :

The

DHT11 is a basic, ultra low-cost digital temperature and humidity sensor. It

uses a capacitive humidity sensor and a thermistor to measure the surrounding

air, and spits out a digital signal on the data pin. Its fairly simple to use,

but requires careful timing to grab data. The only real downside of this sensor

is you can only get new data from it once every 2 seconds, so when using

library, sensor readings can be up to 2 seconds old.

SPECIFICATIONS

The

IR Sensor-Single is a general purpose proximity sensor. Usually it is used for

collision detection or obstacle detection. The module consist of an IR emitter

and IR receiver pair. The high precision IR receiver always detects IR signal.

The module consists of 358 comparator IC. The output of sensor is high whenever

the IR receiver receives a signal of IR frequency and low otherwise. The

on-board LED indicator helps user to check status of the sensor without using

any additional hardware. The power consumption of this module is low. It gives

a digital output.

Features

GAS SENSOR :

MQ

2 Gas sensor

The Grove - Gas

Sensor(MQ2) module is useful for gas leakage detecting. It can detect LPG,

i-butane, methane, alcohol, Hydrogen, smoke and so on.

MQ

6 Gas Sensor

Sensitive

material of MQ-6 gas sensor is SnO2, which with lower conductivity in clean

air. When the target flammable gas exist, the sensor’s conductivity gets higher

along with the gas concentration rising. MQ-6 gas sensor can detect kinds of

flammable gases, especially has high sensitivity to LPG (propane). It is a kind

of low-cost sensor for many applications.

WINDMILL :

A

wind turbine is a device that converts kinetic energy from the wind into

electrical power. The speed of wind on planets like Mars and Jovian gas giant

planets (Jupiter, Saturn, Uranus, and Neptune) is high enough to produce energy

needed by the rover.

The

speed of wind on Mars ranges from 10 mps to 30 mps or 20 miles/h to 60 miles/h.

Currently, the windmill employed on Earth produces 70% of energy at 12 mph and

the power produced by a windmill is 250 W to 1.8 MW. On Jovian planets like

Neptune the speed of wind is 1,100 kph to 2,100 kph. The rover needs 140 W of

energy to operate. So, windmill employed on rover can complete its power

requirements.

To

prevent damage, the windmill stops functioning when the speed of the wind

exceeds 25 mph. Rover can be installed with small windmill which can generate

energy. As, the speed of the wind is more than 25 mph, so, the wings of the

windmill must be strong enough to tolerate the pressure of the high speed wind.

So, small changes made in the windmill can be helpful in installing it on

rovers and can act as a good alternate source of energy for rovers.

RESULT

ANALYSIS AND DISCUSSION

This project

deals with the analysis of results of various sensors. Results of sensors like

Temperature, air, Soil moisture etc. are studied and examined. With the means

of graph the change in values of these

sensors can be studied very accurately. This project helps to deal with the

understanding of those places where it is difficult to analyse the physical and

environmental conditions.

Use of Arduino to program sensors and the

display of graphs have helped a lot in better understanding of project. Until

now the design of this rover is not completely perfect, to make the rover more

useful a lot of changes needed to be done in future so that it can display a wide

variety of data and may help to understand the physical and environmental conditions more clearly and accurately.

CONCLUSION :

This model is designed keeping in view the shortcomings of the models

sent in space. The changes are needed to be made in power supply, balancing and

employment of sensors to search for extraterrestrial life form.

A robotic

spacecraft is a spacecraft with no humans on board, usually under telerobotic

control. A robotic spacecraft designed to make scientific research measurements

is often called a space probe. Many space missions are more suited to

telerobotic rather than crewed operation, due to lower cost and lower risk

factors. In addition, some planetary destinations such as Venus or the vicinity

of Jupiter are too hostile for human survival, given current technology. Outer

planets such as Saturn, Uranus, and Neptune are too distant to reach with

current crewed spaceflight technology, so telerobotic probes are the only way

to explore them.

The increasing

use of automation in future space systems is a fundamental component of future

space exploration which will resemble remotely distributed, net-worked

operations. As such, the design of both manned and unmanned future space

systems has significant HSC (Human Supervisory Control) implications. However,

only a handful of projects have recognized the importance of HSC for future

space systems. In addition to those described previously, Cummings described a

preliminary design for the systems status display of a future lunar landing

vehicle which would have considerably reduced reliance on Mission Control

without compromising the probability of mission success by layering and

grouping information in categories that could be easily and intuitively browsed

on reconfigurable screens. Similar upgrades were planned for the Space Shuttle

cockpit as part of the aforementioned Cockpit Avionics Upgrade. Unfortunately,

these projects were cancelled before they could be implemented in operational

spacecraft. Although technology has progressed rapidly during the last 50 years

of the Space Age, the issues surrounding collaboration between humans and

automation are as relevant today as during the Apollo era, yet space human

supervisory control research has not kept pace with technological advancements.

Significant investment is therefore required not only to develop methodologies

for optimizing human–automation system integration, in order to maximize

mission safety and success at reasonable cost, but also to ensure that the

resulting human centred design

recommendations and requirements are implemented in operational spacecraft,

both manned and unmanned. A strong HSC research and development program will

thus be crucial to achieving the Vision for Space Exploration, especially given

the limited resources under which it must be accomplished.

This project is

designed in a very economical way and unnecessary costing is avoided so that

more attention can be paid to other areas for the improvement of rovers.

FUTURE

SCOPE OF PROJECT

Space Probe are

sent to hostile places where humans cannot reach or survive so the future scope of this project includes the

addition of such sensors which can make it capable to detect hazards, sense the

environment and makes use of AI protocols.

This model is

capable of detecting Temperature and Humidity, Soil Moisture, Gases in

atmosphere. So, it can be used in fields to detect moisture in the soil. It can

be used in cities to detect amount of Carbon present and Smoke hence, it can

detect pollution in the atmosphere. The use of IR sensor enables us to sense

the obstacles present and their distance from such obstacles. Temperature and

Humidity sensor can sense the Temperature and humidity of a place.

Although this

probe has many advantages but future improvements includes the addition of

Camera, More sensors, Radio communication, etc.

More efficient

power supply can be used like radioactive hydrogen cell or chemical fuel cell.

Rover can be

designed in such a way so that it can be capable to bring back samples from

such unfavourable places where humans cannot reach till now.

|

Sunday, 28 June 2015

My Probe

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment